Day 2 :

Keynote Forum

Jan J Dubowski

Université de Sherbrooke, Canada

Keynote: Digital etching of III-V semiconductors in aqueous solutions

Time : 10:25-10:50

Biography:

Professor Jan J. Dubowski received his PhD degree in Semiconductor Physics from the Wroclaw University of Technology, Poland. He is a Canada Research Chair and a full professor at the Department of Electrical and Computer Engineering of the Université de Sherbrooke, Canada. He is a Fellow of SPIE – the International Society for Optics and Photonics (citation: “For Innovative methods of investigation of laser- matter interaction”). He has published over 200 research papers, reviews, book chapters and conference proceedings. He is an associate editor of the Journals of Laser Micro/Nanoengineering, Biosensors and Light: Science & Applications.

Abstract:

Etching of semiconducting materials at rates approaching atomic level resolution is of high interest to the advancement of technologies addressing fabrication of low-dimensional devices, tunability of their optoelectronic properties and precise control of device surface structure. The so- called digital etching that takes advantage of a self-limiting reaction has the potential to address some of these challenges. However, conventional applications of this approach proposed almost 30 years ago, require specialized and expensive equipment, which contributed to a relatively slow progress in penetration of digital etching to micro/nanofabrication processing schemes. We have observed that for photoluminescence (PL) emitting materials with negligible dark corrosion, it is possible to carry out PL-monitored photocorrosion in cycles analogous to those employed in digital etching. The advantage of this approach is that photocorrosion of materials, such as GaAs/AlGaAs heterostructures, could be carried in a water environment. This digital photocorrosion (DIP) process could be carried out in cycles, each approaching sub-monolayer precision. I will discuss fundamentals of DIP and, in particular, mechanisms responsible for achieving high-resolution etch rates of semiconducting materials. For instance, we have demonstrated a successful dissolution of a 1-nm thick layer of GaAs embedded between Al0.35Ga0.65As barriers in a 28% NH4OH:H2O, and we claimed that under optimized conditions a further enhanced resolution is feasible. The nm-scale depth resolution achieved with DIP and low-cost of the instrumentation required by this process is of a potential interest to specialized diagnostics, structural analysis of multilayer nanostructures and, e.g., revealing in situ selected interfaces required for the fabrication of advanced nano-architectures.

We have explored the sensitivity of DIP to perturbations induced by electrically charged molecules, such as bacteria, immobilized on semiconductor surfaces. Here, I will highlight our recent studies on detection of Escherichia coli and Legionella pneumophila bacteria immobilized on antibody functionalized GaAs/AlGaAs biochips. I will also discuss the application of this approach for studying antibiotic reactions of bacteria growing on biofunctionalized surfaces of GaAs/AlGaAs biochips.

Keynote Forum

Hao Gong

National University of Singapore, Singapore

Keynote: Ni-based nanomaterials for high efficiency supercapacitors in energy storage

Time : 11:05-11:30

Biography:

Dr. Hao GONG is a Full Professor of Materials Science and Engineering at National University of Singapore. He is also the coordinator of the transmission electron microscopy laboratory at Department of Materials Science and Engineering. His research interests include transparent oxide conductors and semiconductors (n-type and p-type), energy storage materials and devices (mainly supercapacitors), energy harvest materials and devices (mainly solar cells), gas sensors, functional thin film and nano-materials, materials characterization (mainly on transmission electron microscopy and electron diffraction). Dr. Gong received his B.S. degree in Physics at Yunnan University in 1982. He passed his M.S. courses in Yunnan University, carried out his M.S. thesis research work at Glasgow University, UK, and received M.S. degree of Electron and Ion Physics at Yunnan University in 1987. He then did his PhD at Materials Laboratory at Delft University of Technology, the Netherlands, and obtained PhD degree there in 1992. He joined National University of Singapore in 1992, and is currently full professor at Department of Materials Science and Engineering. He has published about 200 refereed papers in major international journals.

Abstract:

Nanomaterials have special properties, and have important applications in energy storage and many other devices. For energy storage, supercapacitors have attracted great interest and development. Supercapacitor have found a lot of applications in electric cars and other equipment. Different materials have been proposed and used for supercapacitors. In this presentation, high performance supercapacitors based on nanoscale Ni-based materials, which show very high specific capacitance and energy density, are focused. The energy storage performance of such materials and devices are examined and the very high energy storage ability is discussed. Energy storage performance, microstructure, morphology and surface area are found strongly related to Ni and Co oxide structures and morphologies, and the incorporation of some other active materials also enhance performance. 3D core-shell structures contributing to energy storage is presented and discussed. Charged small full supercapacitors prototype will be shown to light up bulb and turn fans for a long time in this presentation.

Keynote Forum

Abdelkhalak EL HAMI

Normandie Université, France

Keynote: Reliability end optimization of embedded mechatronic systems: What applications for the automotive and aeronautics industry

Biography:

Abdelkhalak El Hami, PhD, is a Full Professor at INSA (National Institute of Applied Sciences) of Rouen,- Normandy University, France, as well as Deputy Director of Laboratoire d’Optimisation et FIabilité en Mécanique des Structures (LOFIMS laboratory and Head of mechanical chair of the National Conservatory of Arts and Crafts in Normandy, France. He has been training director of mechanical engineers at INSA-Rouen. Professor El Hami’s research activities include reliability-optimization systems. He is Operator manager INSA Group in Maghreb (Algeria, Morocco and Tunisia)). He has supervised 38 PhD theses. He also is the author and co-author of more than a twenty books and more than 550 papers published in international journals and conferences. He has a doctorate in engineering sciences from the University of Franche-Comté in France (1992). He received his Habilitation diploma to supervise research (HDR) in 2000.

He's Editor in chef of 3 Set of international Book, ISTE, Wiley and Son and Elsivier.

He has award:

1992: Price, Micronora of Piezoelectric actuator

2013: Price, Pepite Noramandy Aerospace

2015: Price, Success story of Moveo, "Pôle de compétitivité international"

Abstract:

Reliability-Based Design Optimization (RBDO) in embedded electronics and mechatronical system is a very important part in several industrial fields. The RBDO analysis of industrial systems is a very important engineering issue, in order to guarantee their functional behavior. Most of the critical failures are generated by the interactions between the sub-systems, implemented in different technologies, e.g. mechanics, electronics, and software. Therefore the analysis of the system as a whole is not enough and it is necessary to study all the interactions in order to estimate the system reliability.

In the embedded electronics and mechatronical system design, it is very important to minimize the structural cost and to maximize safety. Few designers (or researchers) can work with these two opposite philosophies. The basic idea is to know the role of each parameter in our design using advanced technologies in CAD (Computer-Aided Design) domain such as sensitivity analysis, optimization concept and reliability analysis. Our main challenge is to integrate the reliability analysis in the optimization procedure that allows us to define the best compromise between cost and safety. This model is called Reliability-Based Optimization. We applied reliability-based optimization on the three structural optimization families.

Model 1: The Reliability-Based Design Optimization (RBDO) consists of the integration of reliability analysis into the optimization procedure. The classical RBDO approach is carried out in two spaces: normalized space and physical one. Therefore, the nested problems necessitate a high computational time. In order to overcome this problem, we propose a new hybrid formulation consisting in solving the problem in a Hybrid Design Space (HDS), containing all numerical information about the optimization process. Application of Dynamical and fatigue of structures.

Model 2: The Reliability-Based Shape Optimization (RBSO) consists of the coupling between several models: geometrical modeling, numerical simulation, and reliability analysis and optimization methods. The hybrid method can be used efficiently to reduce the computational time. Since the structural geometry may be updated during the optimization process, a flexible model has to be used. After having studied different ways of geometrical modeling, we select a parametric boundary description such as B-spline curves. Furthermore, the design model may be different than the mechanical one and may then give inaccurate results of the structure behavior. We study the relationship between CAD and FEA (Finite Element Analysis) models in order to define the suitable method that updates the geometry with a small cost. Furthermore, the optimization process generally needs gradient evaluations at each iteration. Two problems can be found: the computing time and the result accuracy. Therefore, we propose a new numerical derivative to balance the computing time and the precision. Application of dynamical and noise of structures.

Model 3: The Reliability-Based Topology Optimization (RBTO) is based on the introduction of the reliability criteria into the topology optimization procedure. The resulting reliability-based topologies are different than the resulting deterministic one. Moreover, the advantage of RBTO is to provide the designer with several solutions in function of the target reliability

During this talk, I will present the last developments of Reliability-based Design

Optimization in embedded electronics and mechatronical system.

- Session I

Track 3: Advanced Emerging Materials

Track 5: Materials: Characterization and Applications

Location: West Minster South

Chair

Matheus F A Goosen

Alfaisal University, Saudi Arabia

Co-Chair

Krzysztof Z Sokalski

Czestochowa University of Technology, Poland

Session Introduction

Matheus F A Goosen

Alfaisal University, Saudi Arabia

Title: Suspension thermal sprayed nanocomposite WC-Co coatings: nanoindentation assessment

Time : 11:30-11:50

Biography:

Mattheus (Theo) F. A. Goosen has played key roles in the development of new start up academic institutions. For the past nine years he has held the position of founding Associate Vice President for Research & Graduate Studies at Alfaisal University a private start-up non-profit institution in Riyadh, Saudi Arabia (www.alfaisal.edu). The doctoral degree of Dr Goosen is in chemical & biomedical engineering from the University of Toronto (1981) Canada. Theo has more than 180 publications to his credit including over 133 refereed journal papers, 45 conference papers, 10 edited books and 10 patents. His h index is over 47 and he has well over 8000 citations on Google Scholar. On Scopus he has 133 publications with over 4000 citations. Dr Goosen’s research interests are in the areas of renewable energy, desalination, sustainable development, membrane separations, spray coating technology and biomaterials.

Abstract:

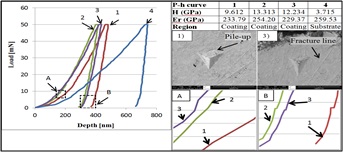

Statement of the Problem: Nanoindentation of WC-12Co thermal spray coatings has been used to evaluate the elastic modulus and hardness of coating on the polished surface of the coatings. While there has been much progress overall, limited research has been reported on the deposition and evaluation of WC-cermet coatings. The aim of this study was to evaluate the microstructural and nanohardness characteristics of tungsten carbide-cobalt (WC-Co) cermet coatings deposited by liquid suspension spraying. Methodology: Commercially available WC-Co coating powder was milled and water based suspension was produced as feedstock for the thermal spray coating process. Microstructural evaluations of WC-Co cermet coatings included XRD (X-Ray Diffraction) and SEM (Scanning Electron Microscopy). Post spraying nanomechanical evaluations were conducted using a Berkovich nanoindenter. Findings: Results indicated relatively higher modulus but lower hardness of suspension coatings. The load displacement curves during nanoindentation were characteristic of the complex coating microstructure showing signs of microcracking and pile-up. The load displacement (P-h) curves along with the SEM images of indents for S-HVOF (suspension high velocity oxyfuel) coating illustrated evidence of sink-in and pile-up of material around the indent contact residual impression during the nano-indentation process. There was some indication of microcracking during indentation as well.

Conclusions: A comparison of S-HVOF and conventional HVOF coatings points toward phase transformations occurring in the suspension spraying which led to nanocrystalline or amorphous phases. The elastic modulus of S-HVOF coatings was on average higher than the conventional HVOF coating. The load displacement curves show features which are consistent with the complex coating microstructure with evidence of micro-cracking and pile-up.

Krzysztof Z Sokalski

Czestochowa University of Technology, Poland

Title: Scaling a way for revealing self-similar features of materials and new applications

Time : 11:50-12:10

Biography:

Research Experience (some events): Dec 1999 – Aug 2016 Research Director, Czestochowa University of Technology, Institute of Computer Sciences Czestochowa, Poland. Oct 1994 – Sep 2002.Professor in Full, Jagiellonian University, Institute of Physics, Cracow, Poland. Visiting Scientist - Integrability of quantum systems, Universiteit Utrecht, Institute for Theoretical Physics Utrecht, Netherlands. Jul 1988 – Sep 1988 Visiting Scientist - Dynamical critical phenomena Universiteit Utrecht, Institute for Theoretical Physics. Apr 1988 – Apr 1988 Visiting Professor - Phase transitions and critical phenomena - lectures for PhD students, The Rockefeller University, New York City, United States Laboratory of Mathematical Physics. Feb 1988 – Oct 1994, Professor (Associate), Head of Soft Condensed Matter Department, Jagiellonian University, Institute of Physics, Kraków, Poland.

Abstract:

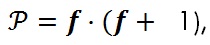

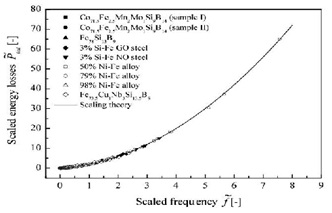

Certain features of certain materials are self-similar. This phenomenon is recognizable by scaling of measurement data corresponding to the considered self-similar feature. To perform scaling we apply notion of homogenous function in general sense. For two independent variables such a function reads P(f,B)=Bβ F(f/Bα), where P is a considered magnitude, α and β are scaling exponents, F(∙) is an arbitrary continuous function, where α, β and F(∙) have to be determined by the measurement data. Definition of P(f,B) enables us to transform all characteristics P(f,B) to the one universal function of the one variable: P(f,B)/ Bβ =F(f/Bα ). This effect is so called the data collapse and can be applied for comparison of measurement data measured in different laboratories, which enable us to estimate quality of each laboratory series. Another application of the data collapse is compression of large experimental data. If the considered data are produced by a self-similar system then one can store them in a form of continuous curve. The data collapse enables us to introduce an absolute dimensionless characteristic:

1), where P and f are dimensionless P and f, respectively. This characteristic divides { P, f } space into the two independent subspaces of materials’ characteristics.

Finally, the scaling supplemented by pseudo-equation of states plays basic role in creation of algorithms for designing of modern materials.

The presented results base on experimental data of Soft Magnetic Materials and Soft Magnetic Composites. Where, P(f,B) is density of power loss, f is frequency of the field’s modulation and B is maximum of magnetic induction. One can apply this simple mathematics to any self-similar object. However, ultimately one must say that the degree of success achieved when applying the scaling depends on the property of the data. The data must obey the scaling.

Etsuji Ohmura

Osaka University, Japan

Title: Laser assist break of hard and brittle materials

Time : 12:10-12:30

Biography:

Dr. Ohmura is a professor of Osaka University. His main field of research is intelligent laser processing systems, especially theoretical analysis and computer simulation to gain deeper understanding of the complicated physical phenomena in laser material processing, influence of laser optics, and nonlinear optical phenomena.

Abstract:

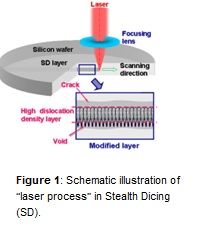

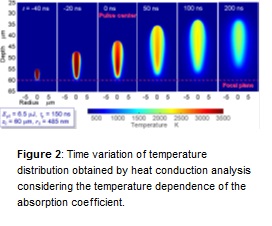

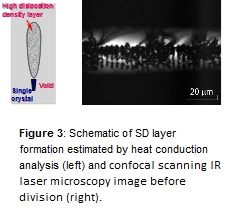

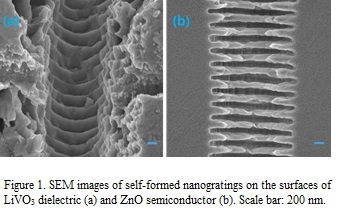

When laser beam with a high energy density is irradiated onto a material, the energy of the beam is converted into thermal energy by absorption, and the temperature rises locally. Thermal diffusion occurs due to a steep temperature gradient. However, as the thermal diffusion time and the thermal diffusion length are very short, a phase change such as fusion, evaporation, sublimation, occurs instantly because energy is added locally in a very short time. The thermal stress caused by this temperature gradient is large and as a result, hard and brittle materials that are difficult to process by mechanical processing can be processed by non-contact processing. Two examples of laser assist break of hard and brittle materials are introduced here. (1) Stealth dicing of the silicon wafer: A permeable nanosecond pulse laser is focused into the interior of a silicon wafer and scanned in the horizontal direction, causing a belt-shaped modified layer to be formed in the wafer (Fig. 1). Applying tensile stress perpendicularly to this modified-layer separates the silicon wafer very easily into individual chips. This method is called “stealth dicing (SD)”. In order to establish a more highly reliable dicing technology and investigate the optimum processing conditions, the formation mechanism of the internal modified layer was studied (Figs. 2 and 3). (2) Laser scribing of glass: Glass sheet is used for flat panel displays, and laser scribing is being used as the separation process. We conducted thermal stress analysis and crack propagation analysis in order to clarify the processing phenomena and control factor.

Ki-Soo Lim

Chungbuk National University, Korea

Title: Self-organized periodic nanostructures on the surfaces of semiconductors and dielectrics by scanning femtosecond laser pulses

Time : 12:30-12:50

Biography:

Ki-Soo Lim is a full professor of physics department at Chungbuk National University in South Korea. He has been working on laser spectroscopy of rare-earth ion doped crystals, glasses, glass-ceramics, and semiconductors. He also studied 3-D bit or holographic data storage in glass, photopolymers and photovoltaic materials. Recent interests and achievements include precipitation and optical properties of glass-ceramics containing fluoride nanocrystals, and micro-nanostructure fabrication on the surface of dielectric materials and polymers by femtosecond laser. He received his B.S. and M.S. degree in Physics at Seoul National University in 1977 and 1980 respectively. He then did his PhD in physics at University of Connecticut, USA, and worked at University of Georgia as a research associate. He joined Chungbuk National University in 1990 after working at Korea Standard Research Institute.

Abstract:

We report the self-formed nanogratings on the surfaces of semiconductors (ZnO and GaN) and dielectric materials (fused silica, borate glass, LiTaO3, LiVO3, sapphire) prepared by scanning focused femtosecond laser pulses at 800 nm with a repetition rate of 1 kHz. Laser fluence range for nanograting self-formation is very narrow. We find a series of periodic-structure orientation is perpendicular to the linear laser polarization. The period of grating structures on the dielectric surface depends on laser power and scan speed, and increases in the range of 200∼300 nm with scan speed and laser pulse energy. In contrast, GaN shows about 600 nm period in the same power range as the dielectric materials. Its period decreases to 450 nm when the laser power is reduced ten times. It also has much lower laser ablation threshold than dielectrics and ZnO, indicating characteristics of metal-like nanogratings due to its high plasma density, large thermal conductivity, and multiphoton absorption coefficients at 800nm. Emission from nanograting area of sapphire indicates the existence of oxygen vacancies. Figure 1 shows the nanograting structure formed by scanning femtosecond laser pulses at 40 μm/s speed of on the surfaces of LiVO3 and ZnO with 0.13 and 0.09 mW power respectively.

For applications, surface nanostructures can be used to improve out-coupling of light in LED. Material absorption can be also significantly enhanced due to surface nano-structures produced by fs-laser pulse processing, applicable to sensing and solar cells.

Lahcène Ouahab

CNRS, Université de Rennes 1, France

Title: Lanthanides-redox ligands for single molecule magnets and luminescence

Time : 12:50-13:10

Biography:

Lahcène Ouahab received his PhD thesis from the University of Rennes1 in 1985. He was “Maître de conférences” at the University of Constantine (Algeria) and then associate Professor at the University of Rennes1 (1988) before getting a permanent position in CNRS as “chargé de recherche” in 1989. He is presently a CNRS director of research and leads the molecular materials research group. He was director of the “Laboratoire de Chimie du Solide et Inorganique Moléculaire UMR6511-CNRS Université de Rennes1” 2004-2006. He was awarded the 1998 prize of the Coordination Chemistry Division, the 2011 Claude Berthault Prize of the “Académie des Sciences” and the 2012 “Grand Prix Pierre Süe” of the French Chemical Society. His fields of research include molecular materials, in particular, multifunctional materials, charge transfer complexes, radical ion salts, organic-inorganic hybrids, polymeric coordination complexes and polyoxometallates

Abstract:

Lanthanide-based complexes have greatly contributed to the development of molecular magnetism in the last decade and more particularly in the branch of single molecule magnets (SMMs). The main reasons are their large magnetic moments associated to their intrinsic large magnetic anisotropy. The splitting of the multiplet ground state of a single-ion in a given environment is responsible of the trapping of the magnetic moment in one direction in SMMs. However, the analyses of the crystal field effects on the magnetic anisotropy are not so common. A better understanding of the magneto-structural correlations in lanthanide-based complexes should provide tools to improve their potentialities. In this presentation we will focus on the specific magnetic properties of TTF-based lanthanide mononuclear and polynuclear complexes. We will show how optimize the SMM behavior playing on i) the modulation of the supramolecular effects via chemical modifications of the TTF ligand, ii) simple molecular engineering modifying the electronic distribution and symmetry of the coordination polyhedron, iii) magnetic dilutions (solution and doping) and iv) isotopic enrichment of the dysprosium.

Haruhiko Morito

Tohoku University, Japan

Title: rystal growth of Na-Si clathrates by the flux method

Time : 14:00-14:20

Biography:

Haruhiko Morito has his expertise in material science and engineering. The main objective of his research is to develop an emerging material which has a new function and new physical properties. In particular, he has developed new functional ceramics containing alkali metals. He has also developed a new crystal growth process based on the binary phase diagram of sodium and silicon. He has synthesized the various silicon-based materials by the sodium flux method.

Abstract:

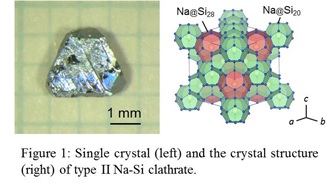

Introduction: Si clathrate compounds have been widely studied due to their unique open-framework structures of Si polyhedrons. Two types of Si clathrates encapsulating Na atoms have been known: type I (Na8Si46) and type II (NaxSi136, 0 < x ≤ 24). These Na-Si clathrates have been generally synthesized by thermal decomposition of a Na-Si binary compound, Na4Si4, at 673–823 K under high-vacuum conditions (<10−2 Pa), and the obtained samples were in the form of powder with a particle size in the micrometer range. The purpose of this study is the crystal growth of the type I and type II Na-Si clathrates by using a Na-Sn flux. Experimental: The starting material of a mixture of Na, Na4Si4, and Na15Sn4 was prepared by heating Na, Si, and Sn (molar ratio, Na/Si/Sn = 6:2:1) at 1173 K in Ar atmosphere. The mixture was heated at 673–873 K for 6–24 h in the container with a temperature gradient. After heating, air-sensitive compounds in the samples, such as Na-Sn compounds, were reacted with ethanol, and the water-soluble reactants were removed by washing with water. Sn present in the products or formed by the ethanol treatment was removed by dissolution in a dilute nitric acid aqueous solution. Results: The single crystals of type I clathrate were crystallized due to the evaporation of Na from the Na-Sn-Si solution at 673–773 K. Most of the single crystals had sizes of several hundred micrometers to 1 mm, and the maximum size reached to about 3 mm. Heating the starting mixture at 823–873 K resulted in the crystal growth of the type II clathrate. The single crystals having {111} habit planes grew up to about 2 mm in size as shown in Fig. 1.

Isaac D Adebiyi

Vaal University of Technology, South Africa

Title: Microstructure and surface properties of Ti-6Al-4V cold spray coated with SiC-based cermet

Time : 14:20-14:40

Biography:

Isaac Adebiyi is a lecturer in the Department of Metallurgical Engineering, Vaal University of Technology, Vandebijlpark, South Africa. He holds a doctoral degree in Metallurgical engineering with specialization in new materials development. His research interests include surface modification of engineering materials (Laser Materials Processing, Cold Spray Coating, High Velocity Oxy Fuel Coating etc.), Additive Manufacturing, Computational Fluid Dynamics Modelling and Simulation, Tribology and Wear Mitigation, Process Optimization, Alloy Design and Physical Metallurgy of Alloys, Microstructure and Phase Evolution Studies, Multifunctional Coatings Development, and Development of Smart and Advanced Materials. He received an award for Innovation and excellence in the use of stainless steel by the Southern African Stainless Steel Development Association. He has authored many publications and has chaired plenary section and moderated international conference.

Abstract:

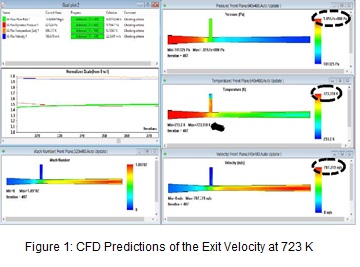

Statement of the Problem: A more ubiquitous application of Ti-6Al-4V in the aerospace industry has been hindered by its poor set of surface properties. The cold spray coating (CSC) process is suitable for improvements in the surface properties but the process is very complex, and highly dependent and sensitive to small changes in its many process parameters. Moreover, the CSC is also very selective of the choice of powder materials. The choice is not only based on application requirements but also on plastic deformability of the powder. Methodology & Theoretical Orientation: This investigation presents a mathematical identification of the optimum process parameters by using a constitutive equation to solve the continuity, momentum and the energy equations governing the flow of fluid through the low-pressure cold spray nozzle. A CFD analysis is performed to determine the input temperature that will yield the calculated velocity by using the meshing tool of Solidworks to analyze the distribution of velocity, temperature, and pressure in the cold spray nozzle and predict their exit values. The optimum parameters were used to deposit a SiC-based cermet on Ti-6Al-4V. The microstructure and phase evolution in the coatings were studied; porosity was measured using ImageJ analysis software; the hardness was measured using Vickers hardness tester; adhesion test was performed according to ASTM C633-1; and the dry sliding wear behaviour was studied in a ball-on-disc configuration using a load of 25 N at a frequency of 5 Hz. Findings: Results show that the initial phases in the feedstock powder were retained in the coatings. No detrimental phase transformation, decomposition and/or decarburization of the SiC. There was peak shift between the phases in the feedstock powder and that of the coatings. This is traced to impact-induced micro-straining, amorphization and grain refinement. A good adhesion strength, and improvements in hardness and wear resistance were obtained in the coated samples although with a higher coefficient of friction which is traceable to higher strength and lack of micro films in the coating. Conclusion & Significance: The improved surface properties of the coating will lengthen the lifespan of the expensive Ti-6Al-4V alloy, leading to significant cost savings for the aerospace industry.

Tengyuan Zhang

Western University, Canada

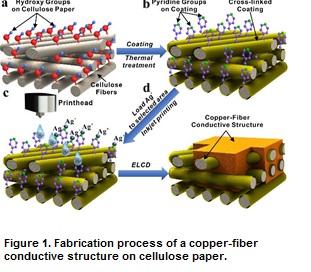

Title: Facile fabrication of hybrid copper-fiber conductive features with enhanced durability and ultra-low sheet resistance for low-cost high-performance paper-based electronics

Time : 14:40-14:55

Biography:

Tengyuan is currently a Ph.D. Candidate of Mechanical & Materials Engineering in Western University, London, Ontario. His research explores printed flexible and stretchable electronics. Based on his research, he co-founded Nectro Inc. in 2015 with the goal of developing novel nano-materials and bringing them to people’s life. Tengyuan was awarded the Vanier Canada Graduate Scholarship in 2015 and won the Doctoral Excellence Research Award in 2016. Now, he looks to combine cutting-edge nanotechnology and advanced chemical/material science to find a robust, low-cost solution for manufacturing high-performance, high-resolution flexible and stretchable electronics.

Abstract:

The accelerating arrival of the Internet of Things (IoT) era creates huge demand for low-cost, high-performance paper electronics. However, fabricating highly conductive circuit on low-cost cellulose paper is challenging due to its high roughness and resolution loss caused by capillary effect.

To address these challenges, we propose a scalable, cost-effective method to fabricate high-performance electronics on regular cellulose paper. Taking advantage of the unique porous structure of cellulose paper, we activate the three-dimensional electroless deposition of copper for fast generation of the hybrid copper-fiber highly conductive structure. Currently, the sheet resistance of most PE product is 50 mΩ/sq. With the technology mentioned above, 5 mΩ/sq (10 times better) can be easily achieved with low cost and high resolution (100 microns feature size). Thanks to its unique copper-fiber hybrid structure, both the physical and electrical properties are greatly enhanced for wider variety of applications. To demonstrate its promising application, a functional battery-free energy harvesting device and a high-performance planar antenna for RFID were fabricated and tested using the proposed method.

Poster Presentation @ 15:10-16:30 in Foyer

Click on Awards category for Poster Presentations

Biography:

Isaac Adebiyi is a lecturer in the Department of Metallurgical Engineering, Vaal University of Technology, Vandebijlpark, South Africa. He holds a doctoral degree in Metallurgical engineering with specialization in new materials development. His research interests include surface modification of engineering materials (Laser Materials Processing, Cold Spray Coating, High Velocity Oxy Fuel Coating etc.), Additive Manufacturing, Computational Fluid Dynamics Modelling and Simulation, Tribology and Wear Mitigation, Process Optimization, Alloy Design and Physical Metallurgy of Alloys, Microstructure and Phase Evolution Studies, Multifunctional Coatings Development, and Development of Smart and Advanced Materials. He received an award for Innovation and excellence in the use of stainless steel by the Southern African Stainless Steel Development Association. He has authored many publications and has chaired plenary section and moderated international conference.

Abstract:

Statement of the Problem: A more ubiquitous application of Ti-6Al-4V in the aerospace industry has been hindered by its poor set of surface properties. The cold spray coating (CSC) process is suitable for improvements in the surface properties but the process is very complex, and highly dependent and sensitive to small changes in its many process parameters. Moreover, the CSC is also very selective of the choice of powder materials. The choice is not only based on application requirements but also on plastic deformability of the powder. Methodology & Theoretical Orientation: This investigation presents a mathematical identification of the optimum process parameters by using a constitutive equation to solve the continuity, momentum and the energy equations governing the flow of fluid through the low-pressure cold spray nozzle. A CFD analysis is performed to determine the input temperature that will yield the calculated velocity by using the meshing tool of Solidworks to analyze the distribution of velocity, temperature, and pressure in the cold spray nozzle and predict their exit values. The optimum parameters were used to deposit a SiC-based cermet on Ti-6Al-4V. The microstructure and phase evolution in the coatings were studied; porosity was measured using ImageJ analysis software; the hardness was measured using Vickers hardness tester; adhesion test was performed according to ASTM C633-1; and the dry sliding wear behaviour was studied in a ball-on-disc configuration using a load of 25 N at a frequency of 5 Hz. Findings: Results show that the initial phases in the feedstock powder were retained in the coatings. No detrimental phase transformation, decomposition and/or decarburization of the SiC. There was peak shift between the phases in the feedstock powder and that of the coatings. This is traced to impact-induced micro-straining, amorphization and grain refinement. A good adhesion strength, and improvements in hardness and wear resistance were obtained in the coated samples although with a higher coefficient of friction which is traceable to higher strength and lack of micro films in the coating. Conclusion & Significance: The improved surface properties of the coating will lengthen the lifespan of the expensive Ti-6Al-4V alloy, leading to significant cost savings for the aerospace industry.

Biography:

Isaac Adebiyi is a lecturer in the Department of Metallurgical Engineering, Vaal University of Technology, Vandebijlpark, South Africa. He holds a doctoral degree in Metallurgical engineering with specialization in new materials development. His research interests include surface modification of engineering materials (Laser Materials Processing, Cold Spray Coating, High Velocity Oxy Fuel Coating etc.), Additive Manufacturing, Computational Fluid Dynamics Modelling and Simulation, Tribology and Wear Mitigation, Process Optimization, Alloy Design and Physical Metallurgy of Alloys, Microstructure and Phase Evolution Studies, Multifunctional Coatings Development, and Development of Smart and Advanced Materials. He received an award for Innovation and excellence in the use of stainless steel by the Southern African Stainless Steel Development Association. He has authored many publications and has chaired plenary section and moderated international conference.

Abstract:

Statement of the Problem: A more ubiquitous application of Ti-6Al-4V in the aerospace industry has been hindered by its poor set of surface properties. The cold spray coating (CSC) process is suitable for improvements in the surface properties but the process is very complex, and highly dependent and sensitive to small changes in its many process parameters. Moreover, the CSC is also very selective of the choice of powder materials. The choice is not only based on application requirements but also on plastic deformability of the powder. Methodology & Theoretical Orientation: This investigation presents a mathematical identification of the optimum process parameters by using a constitutive equation to solve the continuity, momentum and the energy equations governing the flow of fluid through the low-pressure cold spray nozzle. A CFD analysis is performed to determine the input temperature that will yield the calculated velocity by using the meshing tool of Solidworks to analyze the distribution of velocity, temperature, and pressure in the cold spray nozzle and predict their exit values. The optimum parameters were used to deposit a SiC-based cermet on Ti-6Al-4V. The microstructure and phase evolution in the coatings were studied; porosity was measured using ImageJ analysis software; the hardness was measured using Vickers hardness tester; adhesion test was performed according to ASTM C633-1; and the dry sliding wear behaviour was studied in a ball-on-disc configuration using a load of 25 N at a frequency of 5 Hz. Findings: Results show that the initial phases in the feedstock powder were retained in the coatings. No detrimental phase transformation, decomposition and/or decarburization of the SiC. There was peak shift between the phases in the feedstock powder and that of the coatings. This is traced to impact-induced micro-straining, amorphization and grain refinement. A good adhesion strength, and improvements in hardness and wear resistance were obtained in the coated samples although with a higher coefficient of friction which is traceable to higher strength and lack of micro films in the coating. Conclusion & Significance: The improved surface properties of the coating will lengthen the lifespan of the expensive Ti-6Al-4V alloy, leading to significant cost savings for the aerospace industry.

Biography:

Isaac Adebiyi is a lecturer in the Department of Metallurgical Engineering, Vaal University of Technology, Vandebijlpark, South Africa. He holds a doctoral degree in Metallurgical engineering with specialization in new materials development. His research interests include surface modification of engineering materials (Laser Materials Processing, Cold Spray Coating, High Velocity Oxy Fuel Coating etc.), Additive Manufacturing, Computational Fluid Dynamics Modelling and Simulation, Tribology and Wear Mitigation, Process Optimization, Alloy Design and Physical Metallurgy of Alloys, Microstructure and Phase Evolution Studies, Multifunctional Coatings Development, and Development of Smart and Advanced Materials. He received an award for Innovation and excellence in the use of stainless steel by the Southern African Stainless Steel Development Association. He has authored many publications and has chaired plenary section and moderated international conference.

Abstract:

Statement of the Problem: A more ubiquitous application of Ti-6Al-4V in the aerospace industry has been hindered by its poor set of surface properties. The cold spray coating (CSC) process is suitable for improvements in the surface properties but the process is very complex, and highly dependent and sensitive to small changes in its many process parameters. Moreover, the CSC is also very selective of the choice of powder materials. The choice is not only based on application requirements but also on plastic deformability of the powder. Methodology & Theoretical Orientation: This investigation presents a mathematical identification of the optimum process parameters by using a constitutive equation to solve the continuity, momentum and the energy equations governing the flow of fluid through the low-pressure cold spray nozzle. A CFD analysis is performed to determine the input temperature that will yield the calculated velocity by using the meshing tool of Solidworks to analyze the distribution of velocity, temperature, and pressure in the cold spray nozzle and predict their exit values. The optimum parameters were used to deposit a SiC-based cermet on Ti-6Al-4V. The microstructure and phase evolution in the coatings were studied; porosity was measured using ImageJ analysis software; the hardness was measured using Vickers hardness tester; adhesion test was performed according to ASTM C633-1; and the dry sliding wear behaviour was studied in a ball-on-disc configuration using a load of 25 N at a frequency of 5 Hz. Findings: Results show that the initial phases in the feedstock powder were retained in the coatings. No detrimental phase transformation, decomposition and/or decarburization of the SiC. There was peak shift between the phases in the feedstock powder and that of the coatings. This is traced to impact-induced micro-straining, amorphization and grain refinement. A good adhesion strength, and improvements in hardness and wear resistance were obtained in the coated samples although with a higher coefficient of friction which is traceable to higher strength and lack of micro films in the coating. Conclusion & Significance: The improved surface properties of the coating will lengthen the lifespan of the expensive Ti-6Al-4V alloy, leading to significant cost savings for the aerospace industry.