Biography

Biography: Etsuji Ohmura

Abstract

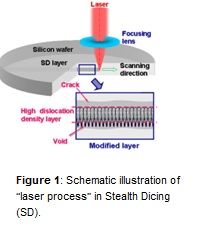

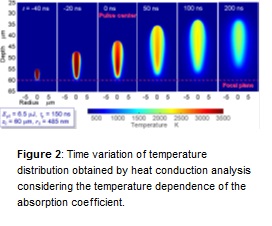

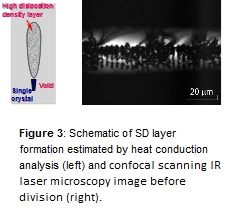

When laser beam with a high energy density is irradiated onto a material, the energy of the beam is converted into thermal energy by absorption, and the temperature rises locally. Thermal diffusion occurs due to a steep temperature gradient. However, as the thermal diffusion time and the thermal diffusion length are very short, a phase change such as fusion, evaporation, sublimation, occurs instantly because energy is added locally in a very short time. The thermal stress caused by this temperature gradient is large and as a result, hard and brittle materials that are difficult to process by mechanical processing can be processed by non-contact processing. Two examples of laser assist break of hard and brittle materials are introduced here. (1) Stealth dicing of the silicon wafer: A permeable nanosecond pulse laser is focused into the interior of a silicon wafer and scanned in the horizontal direction, causing a belt-shaped modified layer to be formed in the wafer (Fig. 1). Applying tensile stress perpendicularly to this modified-layer separates the silicon wafer very easily into individual chips. This method is called “stealth dicing (SD)”. In order to establish a more highly reliable dicing technology and investigate the optimum processing conditions, the formation mechanism of the internal modified layer was studied (Figs. 2 and 3). (2) Laser scribing of glass: Glass sheet is used for flat panel displays, and laser scribing is being used as the separation process. We conducted thermal stress analysis and crack propagation analysis in order to clarify the processing phenomena and control factor.